The wandering axeman Selecting and buying a metal milling machine for the hobbyist

Operation Performed On Milling machine With Diagrams Written by Sachin Thorat in Machine Shop Milling Machine Operations Using Milling Cutters With Diagrams Milling machines are mostly general purposes and have a wide range of applications requiring various types and size of milling cutters.

Milling Machine Parts and their Function HubPages

What is the Milling Machine? Contents show Milling is the machining process in which the removal of metal takes place due to the cutting action of a rotating milling cutter. In a milling machine, the cutter is rotating due to workpiece is fed against it. This machine can hold more than one tool at a time.

PPT Milling Machines PowerPoint Presentation, free download ID2263507

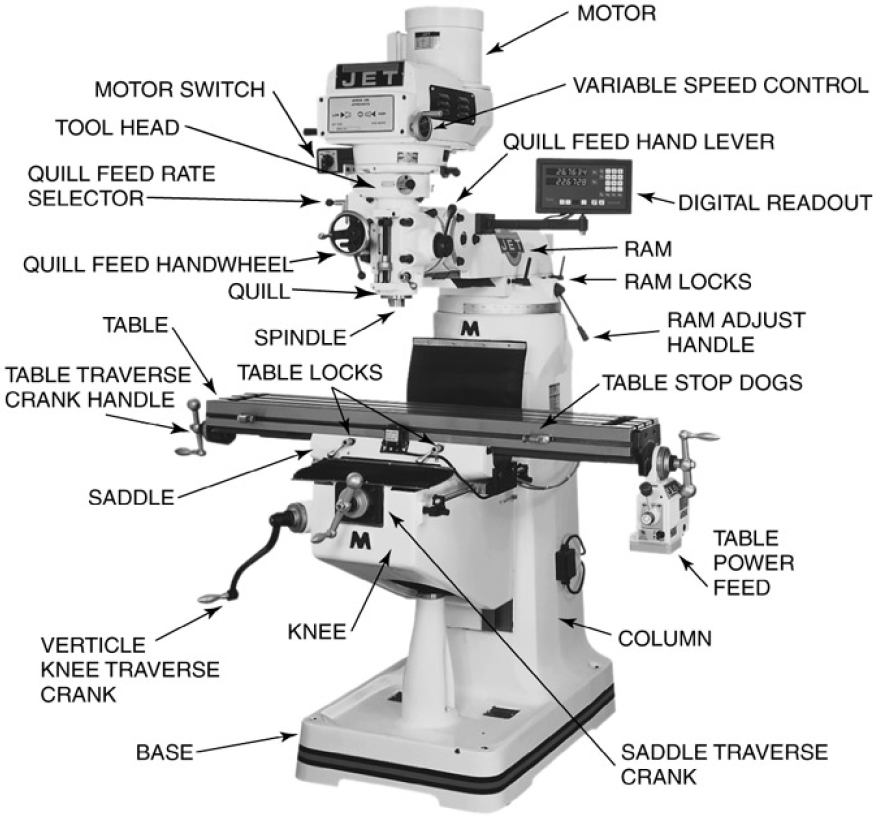

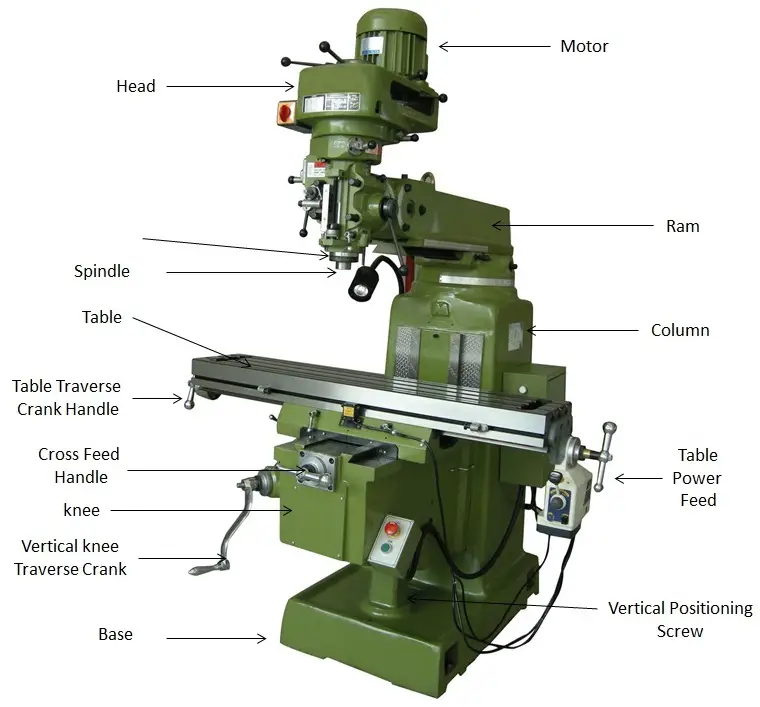

Milling machines with vertical spindles are available in a large variety of types and sizes. The head, which houses the spindle, motor and feed controls, is fully universal and can be placed at a compound angle to the surface of the table. The ram, to which the head is attached, can be moved forward and back and locked in any position.

CNC Milling a Complete Guide to Understand the Process

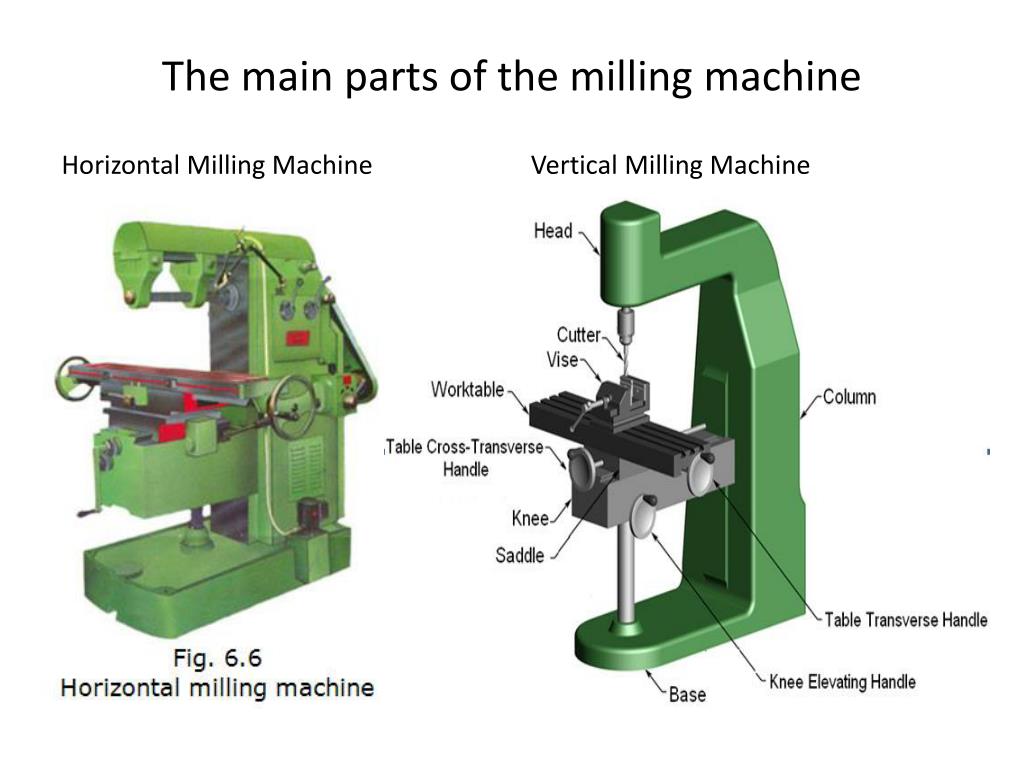

Milling is the process of machining flat, curved, orMilling machines are basically classified as vertical or irregular surfaces by feeding the workpiece against a rotating horizontal. These machines are also classified as knee-type, cutter containing a number of cutting edges. The milling ram-type, manufacturing or bed type, and planer-type.

Universal Milling Machine Diagram ubicaciondepersonas.cdmx.gob.mx

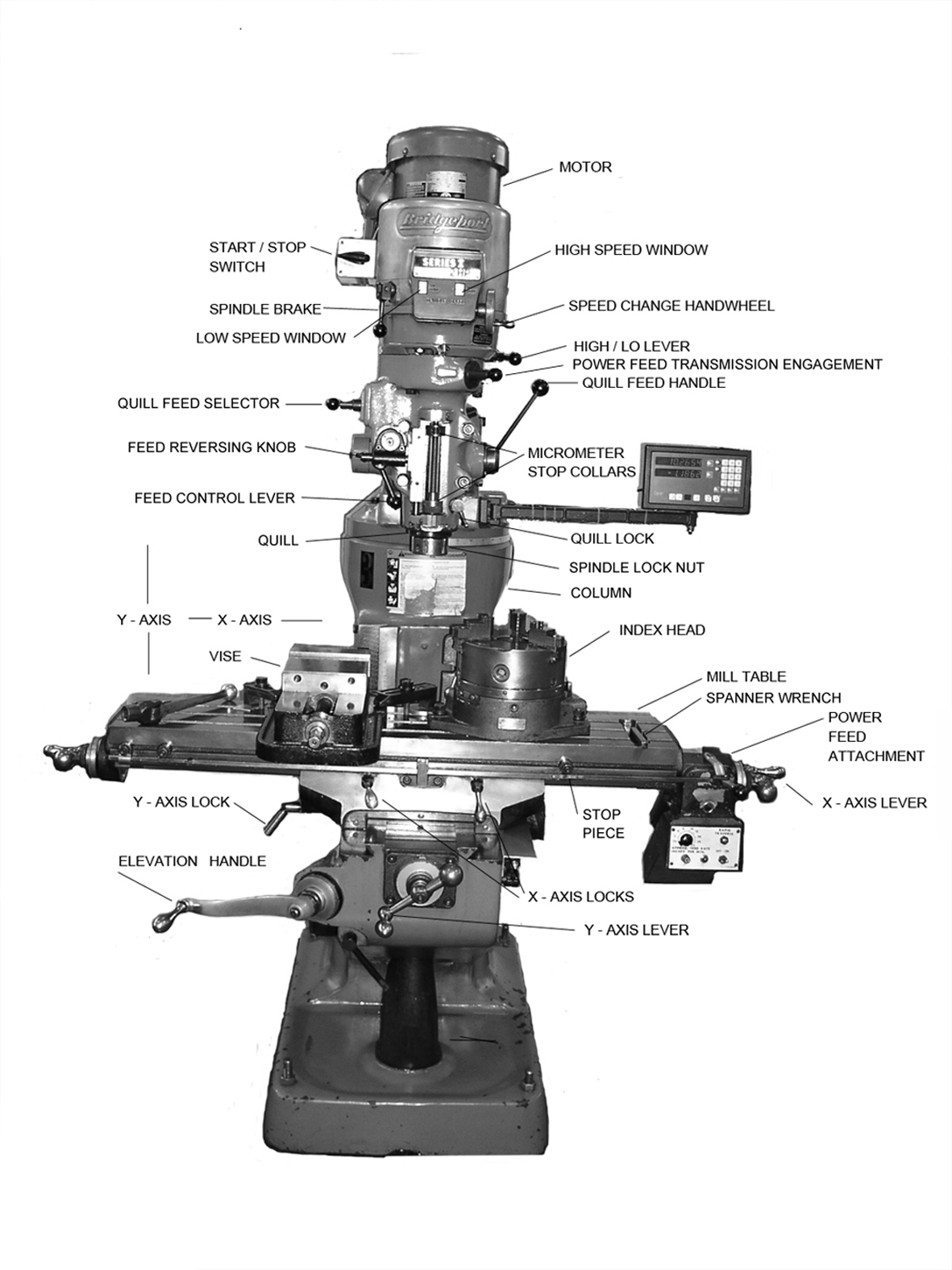

In CNC machining, there are two primary types of milling machines: the vertical milling machine, with a Bridgeport milling machine being an excellent example, and the horizontal milling machine. Although the milling operations on the two styles of milling machines might vary, the milling machine parts that make them up have much in common. We've

[DIAGRAM] Cnc Mill Diagram

13 Parts of a CNC Machine — CNC Block Diagram Learn more about the different parts of a CNC machine and their functions. By Team Xometry December 16, 2022 11 min read

Milling Parts Identification

1. Plain milling machine: also known as horizontal milling machine, a type of rigid and sturdy mill mainly used for machining heavy workpieces, the table can't be rotated, and the part mounted on the worktable can move vertically, longitudinally, and crosswise against the rotating cutter. 2.

Two basic milling operations ( a ) up milling and ( b ) down milling Download Scientific Diagram

VIEWS In this article, we are going to study What is Milling Machine? And it's sub-topics like Introduction, Definition, Main Parts, Operation, Types, Advantages, Disadvantages in detail. Note: The PDF of this article you can download it at the end. Starting with the history first, Milling Machine History: Table of Contents Milling Machine History:

How to Design for CNC Milling

Milling machines are very versatile. They are usually used to machine flat surfaces on square or rectangular parts, but can also produce many unique and irregular surfaces. They can also be used to drill, bore, produce slots, pockets and many other shapes.

The model of CNC milling machine Download Scientific Diagram

There are various components of the general CNC milling machine. Let's see them one by one. 01. Column. The column in case of the CNC Machine is to provide the support and structure to the other machine components. Column acts as a support structure for the milling machine. 02. Machine interface.

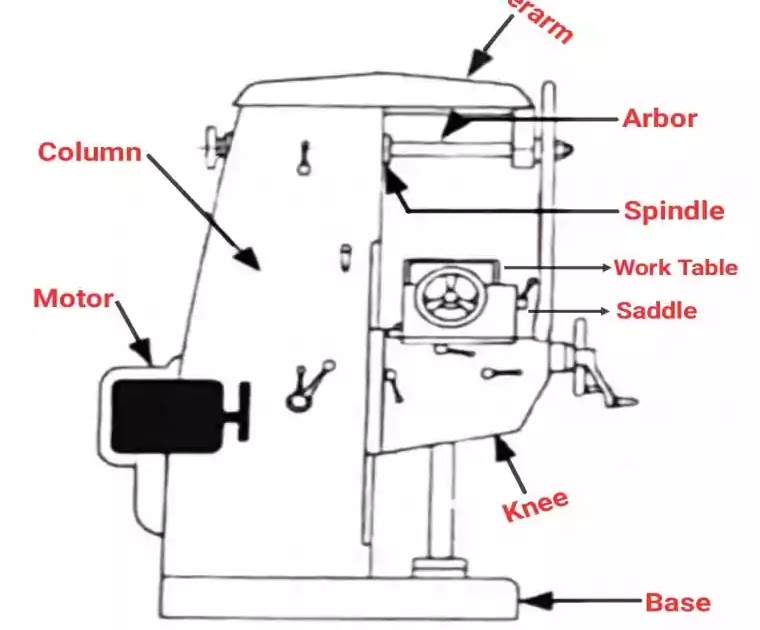

The Horizontal Milling Machine

Milling machine operations are machining processes that involve the use of milling cutters to remove material from a workpiece's surface to achieve specific shapes and dimensions. These operations offer a diverse array of techniques for shaping, cutting, and machining materials with precision and versatility.

Parts of Milling Machine and Their Types,Operation

The process of removing material from a workpiece by advancing rotary cutters cutter into it is called milling. The process is carried out by adjusting pressure, speed of cutter head, and direction of feed. A milling machine is a piece of equipment that removes a layer of material from the surface by using a multi-point cutting tool.

Parts of a CNC Milling Machine Visual Guide MellowPine

[ CNC Milling Machine Parts Home ] A CNC Milling's Axes are attached to the Machine Frame . Their role is to provide motorized motion in each dimension as commanded by the control panel or g-code program through the controller. 3 Axis CNC A typical 3 Axis CNC Milling Machine has it's axes arranged something like this: 3 Axis CNC…

What is Milling Machine Operation, Parts and Types. Mechanical Booster

What is a Milling Machine? It is a machine which is utilized to eliminate metals from the workpiece with the assistance of a revolving cutter called milling cutter. It is utilized to machined the flat, rough and irregular surfaces and this is done by taking care of the workpiece against a rotating milling cutter.

What is Milling Machine? Parts, Operation, Diagram

To obtain 500 to 4200 (high range): Hold the Hi-Neutral-Lo lever (right rear side of the attachment) so the gears are clear of one another. rotate the spindle nose by hand until the gears line up, then move the Hi-Neu-tral-Lo lever to the "Hi" position. Figure 2.14 - Speed Change Handwheel.

Schematic diagram of Efficient and Powerful CNC Milling Machine. Download Scientific Diagram

MILLING MACHINES Revised: August 29, 2005 Manual No. M-450 Litho in U.S.A. Part No. M -0009500-0450 June, 2003 TP5260. Information in this manual is subject to change without notice. This manual covers installation, operation, maintenance, and parts list for Series I milling machines.